Hardware manufacturer WSS makes version leap with the viadat warehouse management system

Smooth upgrade for the warehouse

Wilh. Schlechtendahl & Söhne skipped several versions when updating its warehouse management system. Thanks to comprehensive preparation by viastore's software experts and early, intensive involvement of all employees, the new version was nevertheless installed over the weekend - without jeopardizing the availability of the high-bay warehouse. In a second phase, viadat will also be extended to all warehouse areas - thus significantly increasing the efficiency of the logistics processes once again.

System updates are always an issue - everyone has probably experienced problems with their PC or smartphone after installing the latest software version, for example when it no longer works smoothly with other applications. On the other hand, software updates also make new functions available and only the latest versions promise a high level of protection against cyberattacks.

Two hours buffer, then everything comes to a standstill

While it is still bearable for a personal computer if the update phase does not run completely smoothly, it can be extremely critical for programs used in companies. Take warehouse management systems, for example, which control all storage and retrieval processes in a warehouse: "If our software for controlling the processes in the high-bay warehouse were to fail, our production would come to a standstill after two or three hours at the latest," says Guido Lücker, management spokesman at Wilh. Schlechtendahl & Söhne, WSS for short.

Manufacturer and dealer

With around 300 employees, the company develops and produces fittings for sophisticated door, glass and window technology in commercial building construction and for use in conjunction with steel and aluminum profiles as a façade solution. The products are supplied to metal fabricators on the one hand, and to so-called "system builders", i.e. manufacturers of window and façade systems who use WSS hardware in their solutions, on the other. The high-bay warehouse plays a central role here, says Lücker: "On the one hand, it supplies production with purchased parts as well as the assemblies and products manufactured by us, and on the other hand, shipping orders for customers are picked from the high-bay warehouse." WSS's own products are "married" with purchased trade products, as Guido Lücker calls it. The company is certainly in competition with traditional hardware retailers. "We send between 400 and 600 parcels every day," explains Lücker. "That means we need logistics expertise that a manufacturer doesn't normally need." Instead, WSS acts as a one-stop store where metal fabricators can find all the products they need to complete their task. "A short delivery time for standard products is an important competitive criterion." The company's aim is to deliver ordered items the next day, or the day after that at the latest. "The decisive factor here is ultimately productivity, how well organized the order picking is in terms of effectiveness and efficiency."

WMS has been working reliably for twelve years

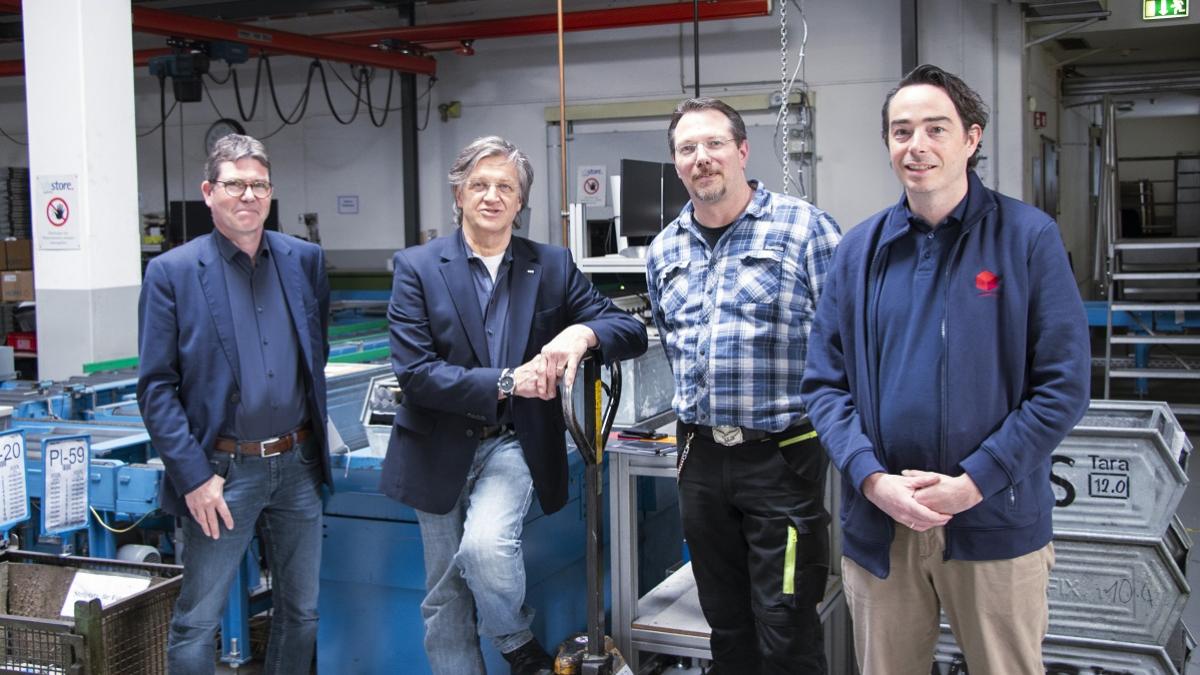

The warehouse management system plays a decisive role here, as the orders could not otherwise be picked efficiently given the large number of products - WSS stocks around 7,000 common products, 28,000 in total. The 25,500 tray storage locations in the high-bay warehouse are managed with viadat, the warehouse management system from viastore. The Stuttgart-based expert for automated storage systems implemented the high-bay warehouse back in 2002. In 2012 and 2013, the warehouse was expanded again by three picking stations to the current six, and the WMS was also updated to the then current version viadat 5.4. "Since then, the system has run reliably and stably," explains Robin Fasel, Managing Director at WSS. "If there were any problems, our own IT specialists or the experts from viastore were able to solve them quickly."

Protection against cyberattacks

However, after twelve years, viadat 5.4 was discontinued and the version number is now 9.3. WSS therefore decided to upgrade to the current version. "This means we can continue to work with permanently maintained software," says Guido Lücker. This is essential simply because of the high availability required, as the management spokesman goes on to emphasize: "The biggest threat to us is cybercrime - a constantly updated version is the best protection against it, so the security level remains consistently high."

Using new functions

Another concrete benefit of the upgrade to viadat 9.3 is the easy customizability of the system, as Mario Schütz, IT Project Manager at viastore, explains: "We can implement simple functionalities much faster and easier than with the old versions." In principle, the warehouse management system can be implemented quickly through configuration and, with more than 2,500 logistics functions, already covers most requirements as standard. However, individual extensions are also possible.

Involving users

The self-explanatory user interface can also be customized: "viastore made special individual adjustments for us users without any problems," explains André Pircher. He is one of the key users appointed by WSS at the beginning of the upgrade project - as such, he was specially trained by viastore on the new software version and was then on hand to help and advise the other employees during the introduction. For Robin Fasel, involving employees in such a project at an early stage is an important success factor: "Trying to do something like this against the will of the people working with the software is a relatively rocky road. It is therefore important to show them the benefits early on and involve them in the project right from the start."

Preparation is important

The company's own employees are one thing. "But the entire process was also very well prepared by viastore," reports Lücker. This included two days of training for all employees who work with viadat. In addition, a viastore expert was available on site for a week after the go-live to answer questions and give tips. In addition, viastore was able to test the entire system on the plant a month before the actual changeover, as Mario Schütz explains: "For example, we were able to test the material flow computers or the interaction with the ERP system using the new software." This meant that any problems discovered could be rectified before the system went live.

In future, all warehouses will be included

The actual upgrade was only the first stage of the entire project. In a second project phase, when the ERP system has also been updated, viadat's tasks are to be significantly expanded once again, as Lücker explains: "Until now, viadat was exclusively responsible for the high-bay warehouse. In future, we also want to have all other warehouse areas controlled by the software." These include various shelving racks, pallet racking and the so-called supermarket, where small parts such as screws for production are stored. These warehouses are currently still managed via the ERP system. By controlling all warehouse areas with viadat, WSS hopes to achieve automatic optimization between the various warehouses, for example based on turnover frequency or other parameters. "Our ERP system can't do that, a warehouse management system like viadat simply offers logistical advantages," says Lücker. Warehouse space should be better utilized and the working hours of warehouse employees used more efficiently, for example through continuous route optimization. "Our aim is to increase the efficiency of our logistics and achieve higher throughputs in order picking," explains Guido Lücker. "We also hope that the support of a software company specializing in logistics will provide us with additional features that an ERP system cannot offer," notes Lücker.

Successful upgrade

The upgrade of the warehouse management system went well for WSS: "With viastore, we have a partner with whom this central element of our logistics is in good hands. Thanks to the good preparations on the part of viastore and the early involvement of the employees, the go-live went completely smoothly within a weekend," reports Lücker. "A success that should not be underestimated when you upgrade several levels up from one version without any major obstacles and it works straight away."